Market demand growth2:: The "2025-2030 China Silicone Industry Market In-depth Research, Development Potential and Investment Research Report" shows that from 2025 to 2030, China's silicone industry will enter a high-quality development stage, and the demand proportion of silicone products in the consumer electronics field will increase to about 35%. With the continuous development of the consumer electronics industry, consumers have increasingly higher requirements for the performance, quality and appearance of electronic products. Silicone products, with their unique performance advantages, will be more widely applied in the field of consumer electronics.

The performance advantage is prominent.:

Good protective performance:Silicone rubber has excellent waterproof, dustproof and shockproof properties. It can be used to make sealing parts and protective cases for electronic products such as mobile phones, tablet computers and headphones. It can effectively protect the precision components inside electronic devices and prevent damage due to external factors3。For instance, the silicone sealing rings on the charging port, headphone jack, camera and other parts of a mobile phone can achieve IP67/IP68 level water and dust resistance3。

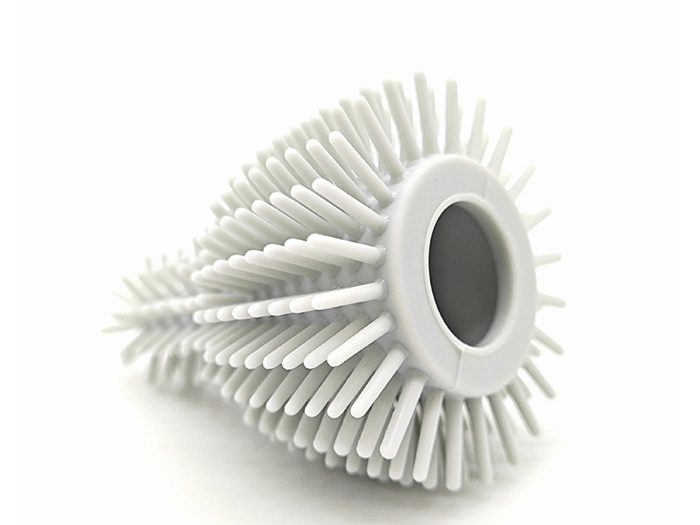

Comfortable touch:Silicone is soft in texture, comfortable to the touch, and has good elasticity and flexibility. It can be used to make mobile phone cases, buttons, wristbands, watch straps and other products, providing users with a comfortable grip and operation experience4。

For example, silicone phone cases can not only protect the phone, but also provide a comfortable grip. The silicone strap of the smartwatch is soft and skin-friendly, providing a comfortable wearing experience.

Excellent temperature resistance and aging resistance:Silicone can maintain stable performance within the temperature range of -60 ℃ to 200℃, is not prone to deformation or brittleness due to high or low temperatures, and has excellent aging resistance. Even after long-term use, it is not likely to crack or harden, making it suitable for various complex usage environments3。Just as electronic products generate heat during long-term use, silicone products can operate stably in high-temperature environments, ensuring their normal use。

Good insulation and anti-electromagnetic interference properties:Silicone is an excellent insulating material that can be used to make insulating protective layers for electronic components, insulating outer sheaths for wires and cables, etc., effectively preventing the occurrence of leakage and short circuits. Meanwhile, silicone also has certain anti-electromagnetic interference performance, which helps to improve the signal quality and stability of electronic products。

Application scenario expansion:

Intelligent wearable devices:With the rapid development of the smart wearable device market, silicone products are increasingly widely used in this field. In addition to the common watch straps and wristbands, it is also applied to the nose pads of smart glasses and the silicone earbuds of in-ear headphones, providing users with a comfortable wearing experience and good sealing effect. For instance, the silicone ear tips of in-ear headphones can better fit the ear canal, enhancing the sound quality and noise insulation effect3。

Foldable screen mobile phone:As an emerging consumer electronic product, foldable screen mobile phones have extremely high requirements for the flexibility and durability of materials. Silicone products, due to their excellent flexibility and tear resistance, can be used to manufacture hinge protection covers, screen frame seals, etc. for foldable screen phones, which helps protect the key parts of foldable screen phones and improve their service life and reliability. For instance, the flexible tactile sensor silicone developed by Shenzhen Sipute has been applied to foldable screen mobile phones of brands such as Xiaomi and OPPO2。

Wireless charging equipment:The popularization of wireless charging technology has led to a gradual increase in the application of silicone products in wireless charging devices. Silicone can be used to make anti-slip pads for wireless charging bases, insulating protective layers for charging coils, etc. It can not only improve the efficiency and stability of wireless charging, but also protect the equipment and prevent it from slipping.

The impetus of environmental protection and sustainable development trends:With the continuous improvement of environmental awareness, consumers' demand for environmentally friendly products is increasing day by day. Silicone materials have the environmental advantages of being recyclable and degradable, which conforms to the trend of green consumption. In the field of consumer electronics, an increasing number of enterprises have begun to adopt silicone products to replace traditional plastic materials in order to reduce environmental pollution. For instance, the Xiaomi 12 Ultra mobile phone adopts an eco-friendly silicone leather back cover, combining environmental protection with performance, which has attracted the attention of consumers.

The impetus of technological innovation3:

Material innovation:: Conductive/thermal silicone has been developed. By adding carbon nanotubes or silver particles, etc., it can be used for electromagnetic shielding or heat dissipation requirements, meeting the demands of consumer electronic products with high heat dissipation requirements such as 5G base station devices and high-performance computers.

Process innovation:: The development of multi-component injection molding, microinjection molding and other processes has enabled silicone products to achieve higher precision and more complex structures, making them suitable for the packaging and protection of miniaturized electronic components such as microelectronic contacts and precision sensors. Meanwhile, the application of real-time process monitoring technology helps to reduce the production defect rate, improve production efficiency and product quality.

Dongguan Guitu Technology Co., Ltd. specializes in customizing silicone rubber products, silicone rubber gift customization, and is a source manufacturer of silicone rubber

Home

Home

Product

Product

News

News

Contact Us

Contact Us